Tools | Compressed Air Quality

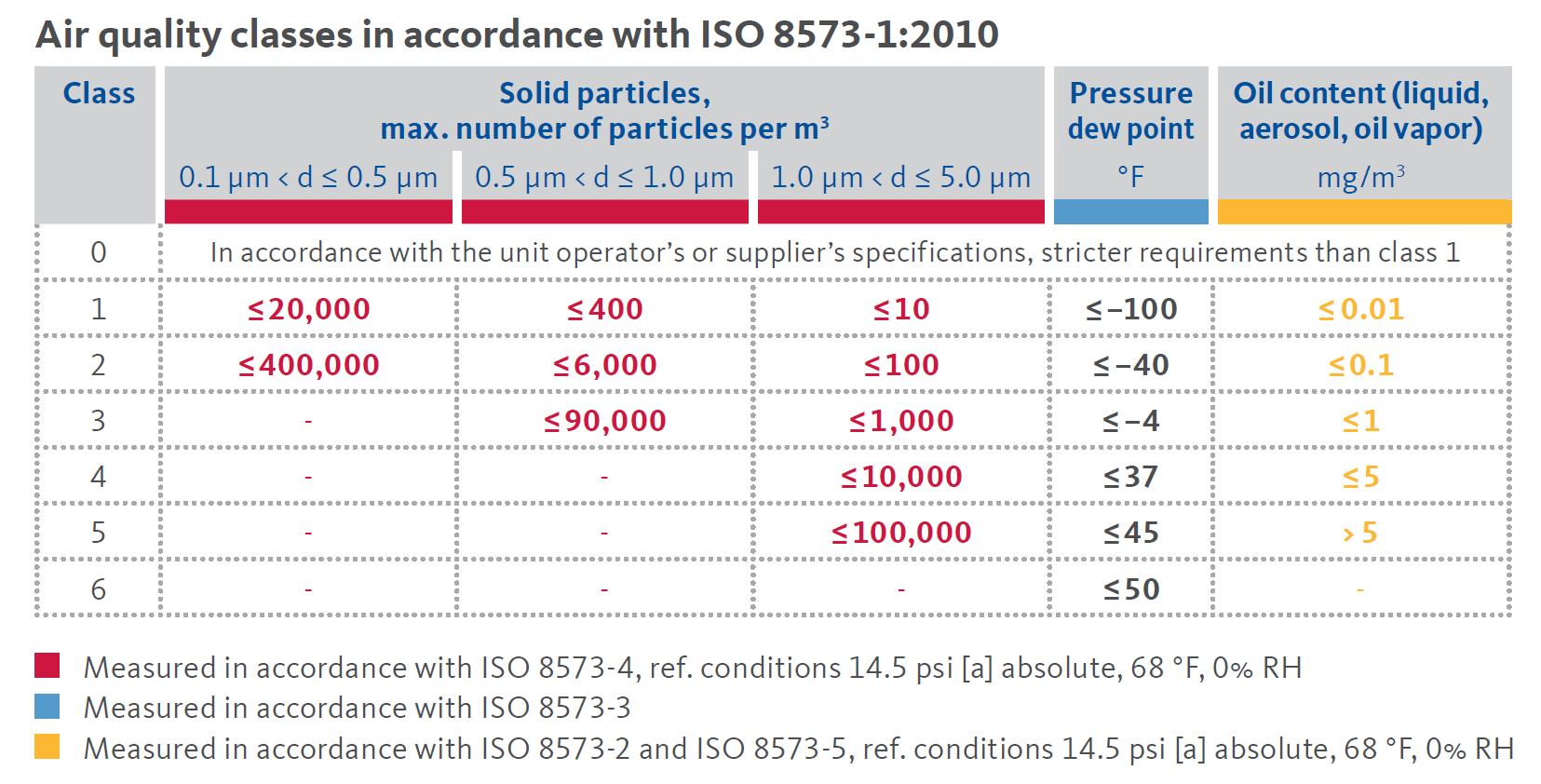

To express a specific quality according to ISO 8573.1, three digits are used, separated by dots. The first digit indicates the particle concentration, the second indicates the humidity, and the third digit the residual oil content including oil vapor. Filling tires, for example, requires quality class 2 for both particle and oil concentration, whereas a spray gun and laser cutting requires class 1 particle and oil content. While class 4 humidity is sufficient for general applications using factory or service air, more complex process engineering applications typically require class 2 to class 1 humidity. Help is just a phone call away, please don't hesitate to contact us now.

Compressed Air Treatment with a System

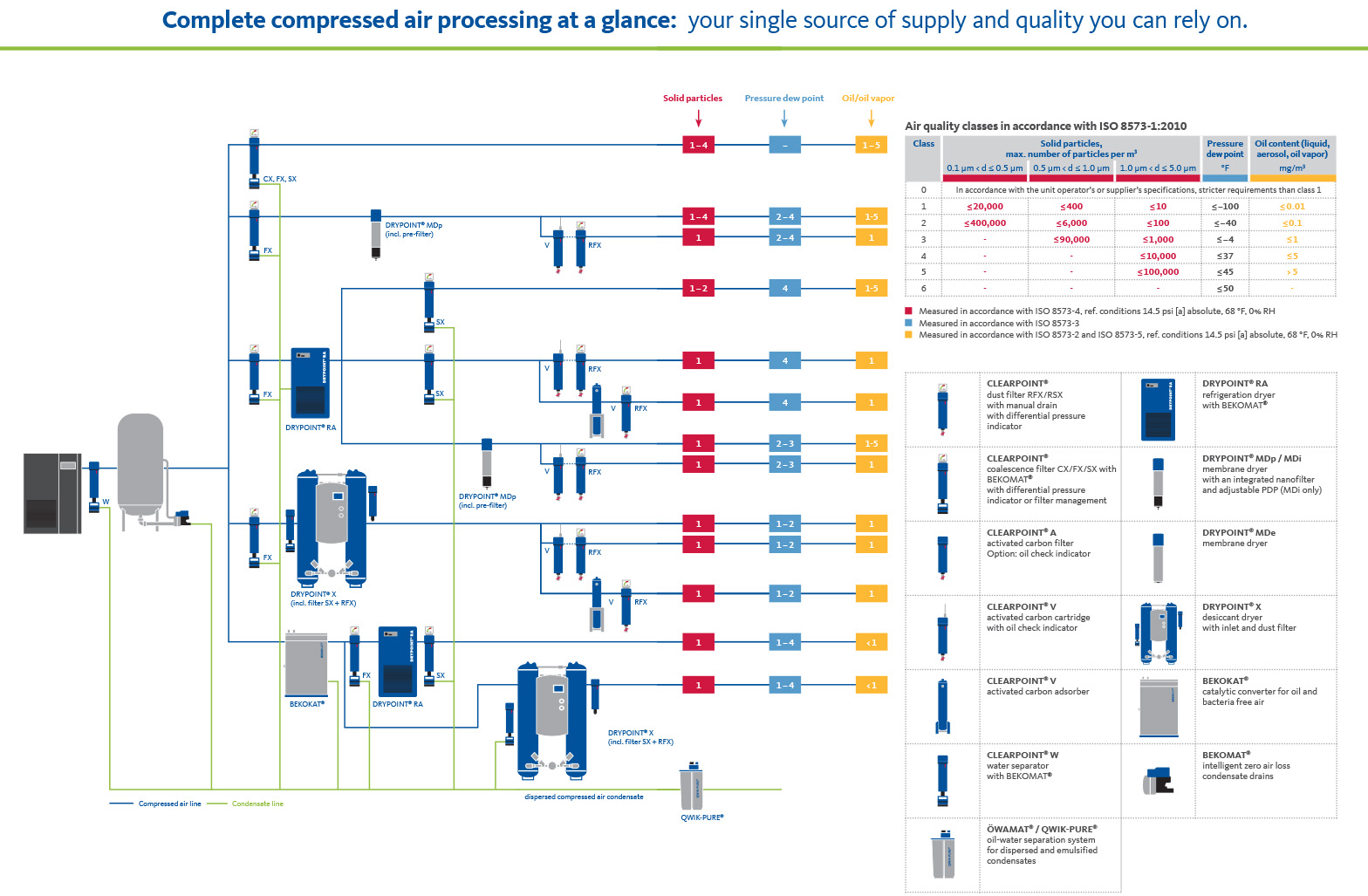

Our compressed air processing at a glance PDF shows an overview with all possibilities and how to achieve a certain compressed air quality with which compressed air treatment products.

Compressed air is an important source of energy in nearly every industry. In which case, the required air quality varies from industry to industry and from application to application. However, the desire for optimal production processes, safe systems, and cost-efficient operations remains the same. We fulfill these requirements all the way from the compressed air generation to the point-of-use application with safe, reliable, and globally proven treatment technology. And thus ensure your success!

Quality is not a Coincidence

Companies face great challenges in production: if product and process safety depend on the quality of the compressed air, then the treatment at the highest level must be ensured at all times. You can only win the trust of consumers if you take responsibility and unconditionally rely on quality assurance. At the same time, the profitability of the processes determines the future viability of the company. Therefore, intelligent energy management is paramount because the energy costs from compressed air generation often amount to more than three quarters of the total costs, so the savings potential in this area is considerable. BEKO TECHNOLOGIES measurement technology helps to identify this tremendous cost saving potential.